Description

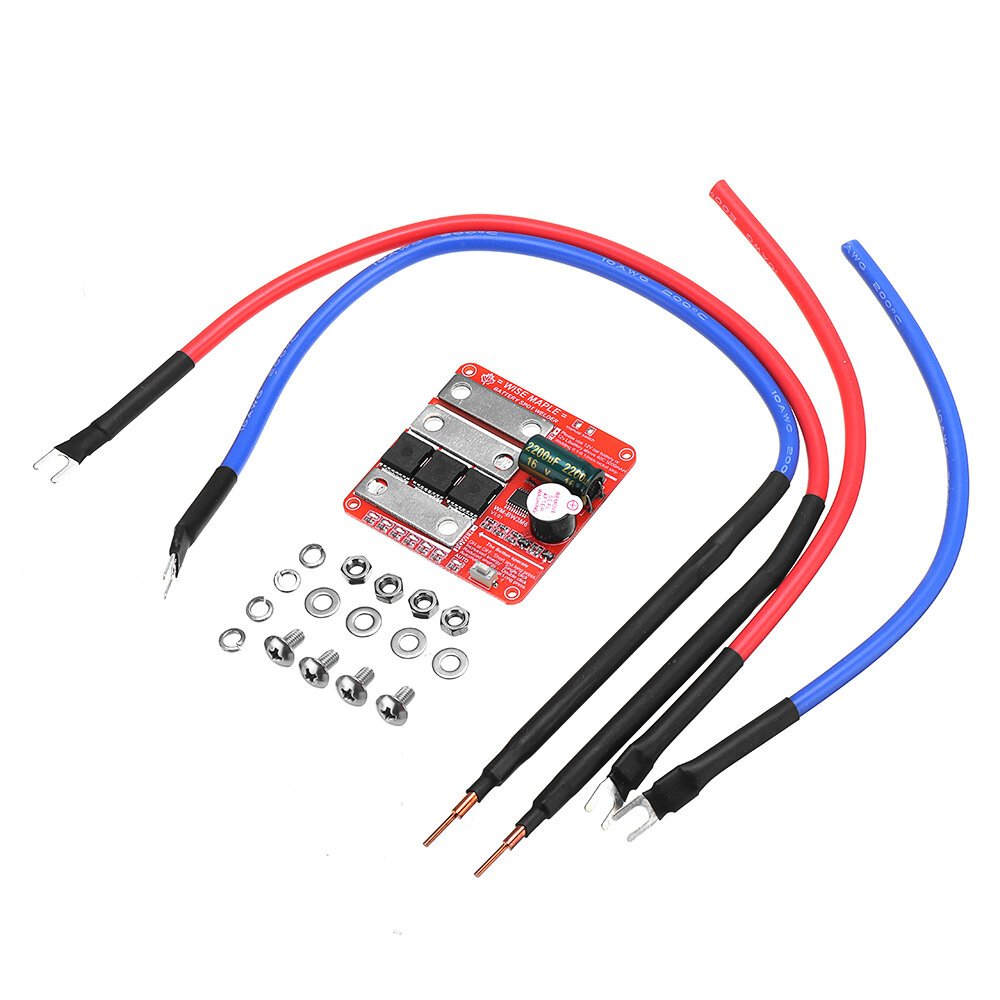

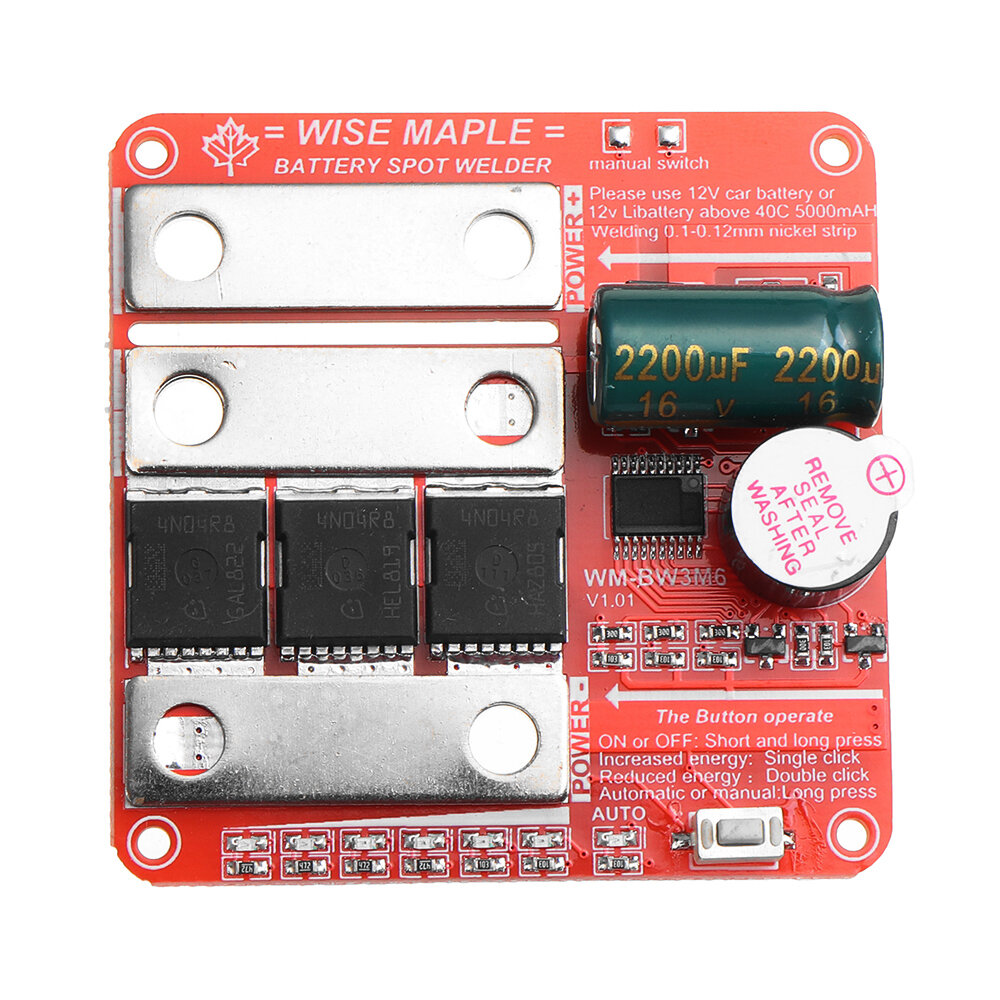

?#1: Control board + spot welding pen#2: Control Panel#3: Spot welding penFeatures:

- 6 levels of energy settings, 6 LED energy indicators.- Automatic welding, keep manual welding interface.- One-key operation, turn on/off/energy adjustment/auto switch.- Thicken the over-current copper bar, reduce the internal resistance and increase the output current capacity.- Bolt connection, convenient and quick.

Power Supply Selection:

This controller can use model airplane batteries, car batteries, polymer lithium batteries, but not super capacitors.1. 25-40Ah 12V car battery, requires good performance and low internal resistance.2. 4000-6000mAh 45C-60C 3S model airplane lithium battery.3. 30-35Ah 12V capacity lithium battery pack.Note: You cannot use super capacitors as power sources.

Nickel Strip Selection:

The thickness of the welding Nickel Strip is between 0.1-0.12mmIf the thickness exceeds this thickness, the MOS tube may burn out.

Instructions:

All operations are performed only through the white buttons on the controller.

Power on and off

In the case of shutdown, click + long press the button to bootIn the case of power on, click + long press to power off

Energy regulation

In the case of power-on, the energy of single-click button increases, and the energy of double-click button decreases.

Automatic/manual switch

In the case of power on, long press the button to switch between automatic/manual welding mode, the blue LED AUTO indicator light is on, it is automatic mode.If you choose automatic mode, set the energy to level 1 first, and then test on the Nickel Strip (dont solder the battery yet). If the welding fails, gradually increase the energy until it can be welded. There is no need to increase energy at this time.

Package Included:

1 x Controller Board1 x Soldering Pen (red+blue)1 x Power Cable (red+blue)1 x Manual

Common Q&A:

1. Poor welding qualityThe reason: (1) Generally, the battery capacity is too small and the ability to discharge current is insufficient (2) The Nickel belt is too thick for weldingSolution: (1) Choose batteries that meet the requirements (2) Weld Nickel belt between 0.1mm-0.12mm

2. Welding explosion, Nickel belt perforationThe reason: (1) Too much energy (2) The soldering pen not firmly pressed (3) There is flammable material under the Nickel beltSolution: (1) Reduce the energy (2) During the welding process, keep the welding needle completely firmly crimped on the Nickel belt (3) During the welding process, no flammable materials must be placed under the Nickel belt.

3. MOS tube burned out during weldingThe reason: (1) battery capacity is too large (2) welding Nickel belt is too thickSolution: (1) Select batteries that meet the requirements (2) Weld Nickel belt between 0.1mm-0.12mm